Huayuan Gaoke Cable Co.,Ltd.

Cinta semiconductora de cobre para cable,Extrusion FRLSOH Funda interior de PVC para cable,N2XSY N2XSEY NA2XSY NA2XSEY N2XSRY NA2XSRY N2XSEBY Cable

Huayuan Gaoke Cable Co.,Ltd.

Cinta semiconductora de cobre para cable,Extrusion FRLSOH Funda interior de PVC para cable,N2XSY N2XSEY NA2XSY NA2XSEY N2XSRY NA2XSRY N2XSEBY Cable

| Tipo de Pago: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Cantidad de pedido mínima: | 500 Meter |

Modelo: N2XSY, N2XSEY, NA2XSY, NA2XSEY, N2XSRY, NA2XSRY, N2XSEBY, N2XSEYBY, NA2XSEBY, N2XSERY, NA2XSERY,

Marca: HUAYUAN YONGTONG

Paquete: Tambores

productividad: 100km/m

transporte: Ocean,Land,Air

Lugar de origen: BEIJING, CHINA

Apoyo sobre: 100KM/M

Certificados : CE CCC ISO

HS-Code: 8544601200

Hafen: Tianjin Port,Shanghai Port,Qingdao Port

Tipo de Pago: L/C,T/T,D/P,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

HOJA DE DATOS TECHNICLA PARA CABLE DE ALIMENTACIÓN DE 33 kV 1C 400 SQmm

| NO. | ITEM | UNIT | DATA |

| 1 | Name of Manufacturer: | Beijing Huayuan Gaoke | |

| Cable Co.,Ltd. | |||

| 2 | Country of Manufacturer: | China | |

| 3 | Which type of manufacturing process viz. Continuous Catanery Vulcanisation (CCV) or vertical Catanery Vulcanisation system (VCV) or horizontal MDCV will be used to ensure circularity and concentricity of the extruded layers around the conductor. | VCV | |

| 4 | Type of Cable: | Cu/XLPE/CWS/PVC/STA/PVC | |

| 5 | Rated nominal voltage | kV | 19/33 |

| 6 | Rated Maximum voltage | kV | 36 |

| 7 | Nominal cross-sectional area of Conductor | Sq.mm | 400 |

| 8 | Conductor | ||

| 8.1 | Material | Copper | |

| 8.2 | Shape & formation | circular | |

| 8.3 | Diameter of conductor | mm | 23.8 |

| 8.4 | Dia.Of Single Wire/Number of strands | mm/ | 2.98/60 |

| 9 | Conductor Screen | ||

| 9.1 | Material | Semi conductor tape + semi conductive material | |

| 9.2 | Thickness of semi-conductor screen | mm | 0.12+0.8 |

| 9.3 | Diameter of Semi-conductor(Approx.) | mm | 25.8 |

| 10 | Insulation | ||

| 10.1 | Material | XLPE | |

| 10.2 | Insulation Thickness(Min.Avg.) | mm | 9.3 |

| 10.3 | Diameter of Insulation(Approx.) | mm | 44.5 |

| 11 | Insulation Screen | ||

| 11.1 | Material | Semi-conductive material | |

| 11.2 | Insulation Screen Thickness | mm | 0.8 |

| 11.3 | Diameter of Insulation screen(Approx.) | mm | 46.1 |

| 12 | Water Barrier | ||

| 12.1 | Material | semi-conducting water swellable tape | |

| 12.2 | Water barrier thickness((Nominal) | mm | 0.3 |

| 12.3 | Diameter of Insulation screen(Approx.) | mm | 47.4 |

| 13 | Metallic Screen: | ||

| 13.1 | Material | Copper wire+ copper tape | |

| 13.2 | Diameter of wire /NO. | mm/ | 0.8/50 |

| 13.3 | Thickness of tape/layer | mm/ | 0.1/1 |

| 13.4 | Cross section of the Metallic Screen | mm2 | 26 |

| 13.5 | Diameter of the cable across the metallic screen(Approx.) | mm | 49 |

| 14 | Bedding | ||

| 14.1 | Material | non-woven fabrics tape | |

| 14.2 | Approximate thickness (Nominal) | mm | 0.2 |

| 14.3 | Diameter of bedding tape (Approx.) | mm | 50 |

| 15 | Inner sheath | ||

| 15.1 | Material | PE laminated Aluminum tape. | |

| 15.2 | Thickness(Nominal) | mm | 0.2 |

| 15.3 | Diameter Over the inner sheath (Approx.) | mm | 51 |

| 16 | Extrusion Inner sheath | ||

| 16.1 | Material | FRLSOH PVC | |

| 16.2 | Thickness(Nominal) | mm | 1.6mm |

| 16.3 | Diameter (Approx.) | mm | 54.2 |

| 17 | Armouring | ||

| 17.1 | Material | Nonmagnetic steel tape | |

| 17.2 | Thickness /layer | mm/ | 0.5/2 |

| 17.3 | Diameter (Approx.) | mm | 56.2 |

| 18 | Outer Sheath | ||

| 18.1 | Material | FRLSOH PVC | |

| 18.2 | Outer Sheath Thickness(Nominal) | 2.9 | |

| 18.3 | Over Diameter(Approx.) | 62 | |

| 19 | Conductor Weight | kg/km | 3542 |

| 19.1 | Total Cable Weight (Approx.) | kg/km | 7185 |

| 19 | Minimum Bending Radius | ||

| 19.1 | During Installation | mm | 950 |

| 19.2 | Installed | mm | 600 |

| 20 | Maximum Pulling Tension | ||

| 20.1 | Of Conductor | kN | 28 |

| 21 | Continuous current rating under the specified installation and operating conditions. Conductor temperature 90° C . Ground temperature 35° C and depth of laying 1500 mm | ||

| 21.1 | In Air | Amp | 629 |

| 21.2 | In Ground | Amp | 465 |

| 21.3 | In pipeline | Amp | 438 |

| 22 | Maximum value of electric stresses at the conductor screen (Calculation to be shown separately) | kV/mm | 2.72 |

| 22.1 | Maximum value of dielectric stress at the insulation | kV/mm | 1.57 |

| 23 | Short circuit capacity of conductor for 1/2/3 second assuming conductor temperature of 90 ° C prior to short circuit and 250 ° C during short circuit | ||

| 23.1 | 1.0 Secs | kA | 57.4 |

| 23.2 | 2.0 Secs | kA | 40.7 |

| 23.3 | 3.0 Secs | kA | 33.3 |

| 24 | Short circuit capacity of metallic screen for 1/2/3 second at screen temperature of 80 ° C prior to short circuit and 200 ° C during short circuit | ||

| 24.1 | 1.0 Secs | kA | 3.4 |

| 24.2 | 2.0 Secs | kA | 2.4 |

| 24.3 | 3.0 Secs | kA | 2 |

| 25 | Screen voltage under maximum operating conditions assuming all circuits connected | kV per km | 0.05 |

| 26 | TEST | ||

| 26.1 | Maximum D.C. resistance of conductor per km. at 20 degree C. | Ohm | 0.047 |

| 26.2 | Maximum A.C. resistance of conductor per km. at 90 degree C. | Ohm | 0.0614 |

| 26.3 | Maximum electrostatic capacitance per km. of cable. | μF | 0.233 |

| 26.4 | Partial discharge at 1.50 Uo | pc | ≤ 10 |

| 26.5 | A.C. Enduring Test voltage 2.5U0/ hours | kV/mim | May-70 |

| 26.6 | D.C.Out sheath Enduring Test voltage | kV/mim | 5kV/1min |

| 26.7 | Impulse test voltage | kV | 170 |

| 27 | Approximate drum dimension (dia & width) | mm/mm | 2200*1400 |

| 28 | Maximum length of cable in a drum (Metres) | m | 600 |

| 28.1 | Minimum length of cable in a drum (Metres) | m | 500 |

| 29 | Approximate gross weight of cable in a drum | TON | 4.3 |

| 30 | Expected Cable life. | Year | 30 |

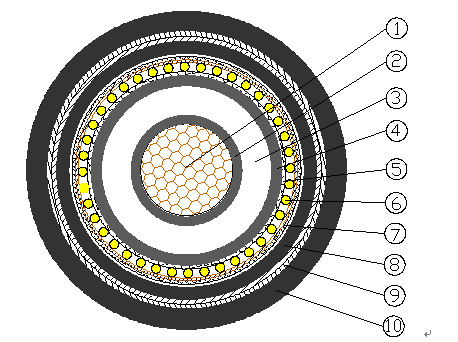

Dibujo de configuración

CU / XLPE / CWS / PVC / STA / PVC 19/33 (36) kV 1C 400 mm 2

|

Construction |

Thickness(mm) |

Diameter(mm) |

|

1 --- Copper conductor |

|

23.8(+0.2,-0.2) |

|

2 --- Semi conductor tape +conductor screen |

0.12+0.8 |

25.8 |

|

3 --- Insulation |

9.3 |

44.5(+0.5,-0.5) |

|

4 --- Insulation screen |

0.8 |

46.1 |

|

5 ---Semi-conducting swelling tape |

0.3 |

47.4 |

|

6 --- Copper wires +Copper tape |

0.8+0.1 |

49.0 |

|

7 ---Inner shearh(bedding tape+ PE laminated Aluminum tape.) |

0.2+0.2 |

51.0 |

|

8 --- Extrusion FRLSOH PVC Inner sheath |

1.6 |

54.2 |

|

9 --- Double nonmagnetic steel tape armouring |

0.5 |

56.2 |

|

10---FRLSOH PVC outer sheath |

2.9 |

62.2(+2.0,-2.0) |

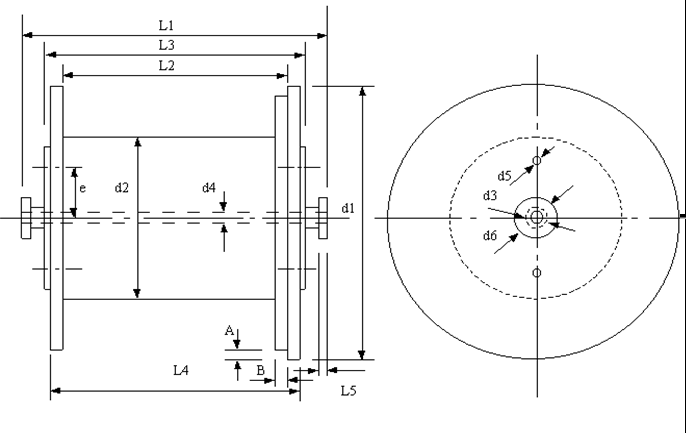

Tambor

d1: 2200 mm

L1: 1400 mm

500m por tambor

H: 2200 mm

L: 2200 mm

W: 1400 mm

Wight: 200 kg

Equipos avanzados de fabricación

Equipos de prueba avanzados

La compañía presentó el equipo de prueba y producción de alambres y cables de nivel avanzado del mundo, como el analizador de espectro DV-6E, el probador de impurezas en micro poros en línea, etc.

Advanced Testing Equipment Guarantee Producción de alta calidad

1.33k Cable 2.Three Core Copper Conductor 3.Five Core Copper Conductor 4.Copper Wire Cable blindado 5.Mv Xlpe Cable

PRODUCTOS POR GRUPO : Cable de alimentación de voltaje medio